Aircraft safety relies on rigorous maintenance, divided into three categories: line maintenance for routine checks, base maintenance for scheduled inspections, and heavy maintenance for extensive overhauls. These procedures, guided by strict regulations, ensure millions of passengers travel safely every day.

Line Maintenance: Daily Operations and Quick Fixes

Line maintenance encompasses all routine checks and repairs performed on aircraft between flights or during short turnarounds. This maintenance category ensures aircraft remain airworthy for immediate operations without requiring extensive downtime.

Scope and Common Tasks

Line maintenance technicians perform pre-flight, transit, and overnight checks that typically last from 30 minutes to several hours. These checks include visual inspections of the aircraft exterior, engine components, landing gear, and control surfaces. Technicians verify fluid levels, tire pressure, and basic system functionality.

Common line maintenance tasks include:

- Oil level checks and fluid top-offs

- Minor repairs to cabin equipment

- Replacement of burned-out lights

- Tire changes when necessary

- Basic troubleshooting of aircraft systems

- Documentation of any discrepancies found during inspection

Frequency and Timing

Airlines schedule line maintenance around flight operations to minimize delays. Pre-flight checks occur before each departure, while overnight maintenance happens during longer ground stops. Most line maintenance tasks can be completed at the gate or on the ramp, allowing aircraft to return to service quickly.

The frequency depends on flight schedules and regulatory requirements. Some checks occur before every flight, while others may happen weekly or after a specific number of flight hours.

Example Scenarios

Consider a typical scenario: an aircraft lands after a three-hour domestic flight. While passengers disembark and the cabin crew prepares for the next departure, an aircraft mechanic performs a walk-around inspection. They discover a small crack in a navigation light cover. Within 20 minutes, the technician replaces the cover, documents the repair, and clears the aircraft for its next flight.

Another common example involves addressing passenger complaints about non-functioning entertainment systems. Line maintenance technicians can often resolve these issues quickly by resetting systems or replacing faulty components, ensuring passenger satisfaction without delaying departure.

Base Maintenance: Comprehensive Scheduled Overhauls

Base maintenance involves more extensive inspections and repairs that require aircraft to be removed from service for extended periods. These checks occur at specialized maintenance facilities equipped with hangars, specialized tools, and comprehensive spare parts inventories.

Scope and Common Tasks

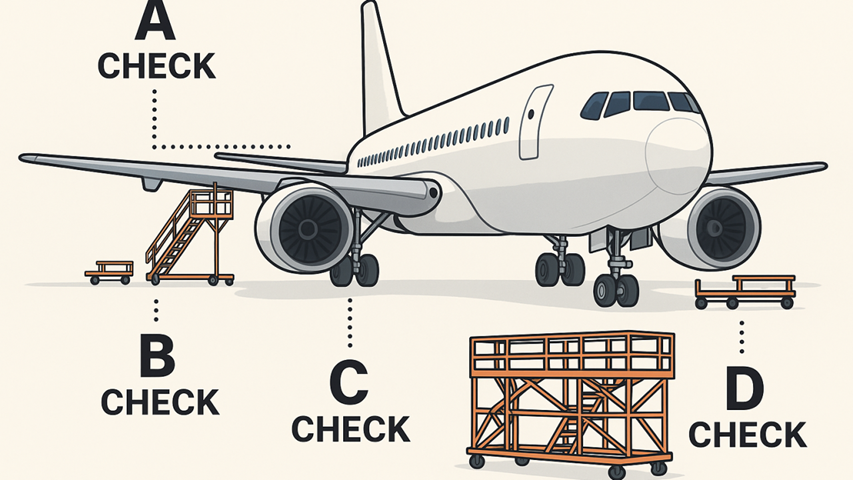

Base maintenance includes A-checks, B-checks, and C-checks, each progressively more comprehensive. These inspections involve detailed examinations of aircraft systems, structures, and components that cannot be adequately assessed during line maintenance.

Typical base maintenance activities include:

- Detailed structural inspections using specialized equipment

- Engine borescope inspections

- Hydraulic system pressure tests

- Electrical system continuity checks

- Interior refurbishment and deep cleaning

- Compliance with service bulletins and airworthiness directives

- Component replacement based on life limits or condition

Frequency and Timing

Airlines schedule base maintenance based on flight hours, calendar time, or flight cycles, whichever comes first. A-checks typically occur every 400-800 flight hours, while C-checks happen every 4,000-6,000 flight hours or 18-24 months.

These maintenance events require careful planning to minimize impact on airline operations. Airlines often schedule base maintenance during low-demand periods or coordinate with maintenance facilities months in advance.

Example Scenarios

A Boeing 737 approaching its C-check interval enters a maintenance hangar for a scheduled 10-day inspection. Technicians remove interior panels, access panels, and inspection covers to examine areas normally inaccessible during line maintenance. They discover corrosion on a structural element requiring repair and replacement of surrounding fasteners.

During the same C-check, maintenance teams replace time-expired components, update cabin interiors, and perform mandated modifications. The aircraft emerges fully refreshed and compliant with all regulatory requirements, ready for thousands more hours of safe operation.

Heavy Maintenance: The Most Comprehensive D-Check

Heavy maintenance, commonly known as D-checks, represents the most extensive maintenance activity in commercial aviation. These comprehensive overhauls can take 20-60 days and involve virtually complete aircraft disassembly and inspection.

Scope and Detailed Inspection Process

D-checks involve removing aircraft from service for comprehensive structural inspections, major component overhauls, and significant modifications. Maintenance teams strip aircraft interiors, remove engines, and access every structural element for detailed examination.

The inspection process includes:

- Complete structural teardown and inspection

- Non-destructive testing using ultrasonic and eddy current methods

- Major component overhauls or replacements

- Paint stripping and repainting

- Interior complete refurbishment

- Avionics system upgrades

- Compliance with accumulated service bulletins

Frequency and Timing

D-checks typically occur every 20,000-25,000 flight hours or 10-12 years, depending on aircraft type and operating conditions. Airlines carefully plan these events years in advance due to their significant cost and operational impact.

The timing often coincides with major fleet decisions, interior refreshes, or regulatory compliance deadlines. Some airlines coordinate D-checks with aircraft lease returns or major route restructuring.

Example Scenarios

A 15-year-old Airbus A320 enters heavy maintenance for its second D-check. Over six weeks, maintenance teams remove seats, galleys, and lavatories. They strip paint from the fuselage, revealing the underlying aluminum structure for comprehensive inspection.

Technicians discover fatigue cracking around door frames requiring structural repair. They also update the aircraft with new avionics systems, install fuel-efficient winglets, and completely refurbish the interior with modern seating and entertainment systems. The aircraft emerges essentially renewed, ready for another decade of reliable service.

Regulatory Oversight: Ensuring Compliance and Safety

Aviation maintenance operates under strict regulatory oversight from authorities like the Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) in Europe. These organizations establish comprehensive maintenance requirements ensuring consistent safety standards across the industry.

Importance of Regulations

Regulatory frameworks mandate specific maintenance intervals, procedures, and documentation requirements. Airlines must demonstrate compliance through detailed record-keeping, certified technician qualifications, and regular audits.

These regulations establish minimum standards while allowing airlines flexibility in developing maintenance programs suited to their specific operations and aircraft utilization patterns. The regulatory structure ensures maintenance quality remains consistently high regardless of airline size or geographical location.

Compliance and Safety Standards

Maintenance organizations must obtain specific certifications and approvals to perform work on commercial aircraft. These certifications require demonstrated capabilities, qualified personnel, and quality systems meeting regulatory standards.

Regular inspections by regulatory authorities verify ongoing compliance and identify areas for improvement. This oversight system creates multiple layers of safety assurance, from individual technician certifications to organizational quality systems.

Conclusion

Airplane maintenance is crucial to aviation safety, encompassing three key types: line maintenance for daily readiness, base maintenance for periodic inspections, and heavy maintenance for long-term overhauls. Supported by strict regulations, these processes ensure millions of safe flights each year, thanks to the tireless efforts of aviation professionals.