Fluid flow can be smooth and orderly or chaotic and mixed, with this distinction playing a critical role in small channels. These flow patterns affect heat transfer, mixing efficiency, and pressure, influencing the performance of medical devices, industrial processes, and biological systems.

Understanding Flow Patterns

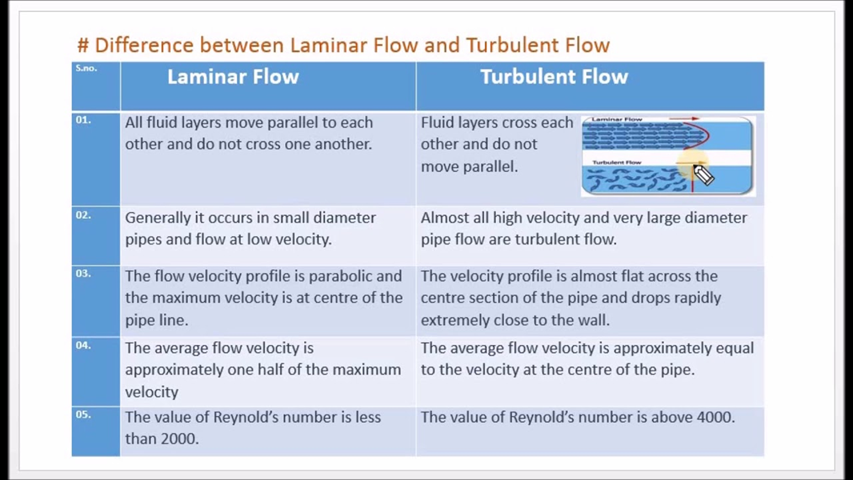

Laminar flow occurs when fluid moves in smooth, parallel layers with minimal mixing between them. Each layer slides past adjacent layers without disruption, creating predictable streamlines that remain constant over time. This orderly movement resembles sheets of paper sliding over one another, with the fluid closest to the channel walls moving slowest due to friction.

Turbulent flow presents the opposite behavior. Fluid particles move in irregular, chaotic patterns with constant mixing and swirling motions called eddies. Velocity fluctuates randomly at any given point, and the flow pattern changes continuously. This chaotic motion enhances mixing but also increases energy losses and pressure drops.

The transition between these flow types depends primarily on the Reynolds number, a dimensionless parameter that compares inertial forces to viscous forces within the fluid. For circular pipes, laminar flow typically occurs when the Reynolds number stays below 2,300, while turbulent flow dominates above 4,000. Between these values lies a transitional region where flow can switch between patterns.

Laminar Flow Characteristics in Small Channels

Small channels strongly favor laminar flow due to their geometry and the physics involved. As channel dimensions decrease, the surface area to volume ratio increases dramatically, amplifying the effects of viscous forces relative to inertial forces. This shift makes it much easier to maintain the low Reynolds numbers that promote laminar conditions.

The velocity profile in laminar flow through small channels follows a predictable parabolic shape. Fluid moves fastest at the center of the channel and gradually slows toward the walls, where viscous friction brings it nearly to a stop. This creates a smooth gradient across the channel width, with maximum velocity approximately twice the average velocity.

Heat transfer in laminar flow occurs primarily through conduction rather than convection. Without the chaotic mixing of turbulent flow, thermal energy moves slowly from the heated walls toward the center of the channel. This process becomes more efficient in smaller channels because the reduced distance allows conduction to work more effectively.

Pressure drop in laminar flow follows well-established mathematical relationships. The Poiseuille equation accurately predicts pressure losses for fully developed laminar flow in circular channels, showing that pressure drop increases linearly with flow rate and inversely with the fourth power of diameter. This relationship explains why even small reductions in channel size create dramatic increases in required pumping pressure.

Turbulent Flow in Small Channels

Achieving truly turbulent flow in very small channels requires extremely high velocities or specific channel geometries. The small dimensions naturally suppress turbulence by increasing the relative importance of viscous forces, which tend to dampen chaotic motions before they can fully develop.

When turbulent flow does occur in small channels, it differs significantly from turbulence in larger systems. The mixing length—a measure of how far fluid particles can move before being affected by viscous forces—becomes constrained by the channel walls. This constraint limits the size and intensity of turbulent eddies, creating what researchers call “constrained turbulence.”

Heat transfer improves dramatically in turbulent flow because chaotic mixing rapidly distributes thermal energy throughout the fluid. Hot fluid near the walls mixes with cooler fluid in the center, creating more uniform temperatures and higher overall heat transfer rates. However, this benefit comes at the cost of significantly higher pressure drops.

The pressure losses in turbulent flow increase roughly with the square of velocity, compared to the linear relationship in laminar flow. This nonlinear relationship means that small increases in flow rate can cause large increases in required pumping power, making turbulent flow expensive to maintain in small channels.

Biological Applications and Parallels

The human circulatory system provides an excellent example of flow patterns in small channels. Blood flow in large arteries can become turbulent, especially during exercise when flow rates increase dramatically. However, flow in capillaries—the smallest blood vessels—remains laminar due to their microscopic dimensions and relatively low flow velocities.

This laminar flow in capillaries serves important biological functions. The smooth flow pattern allows red blood cells to align themselves efficiently as they squeeze through vessels barely larger than their own diameter. Insights from this natural process are often applied to microfluidic chip design, where controlled laminar flow is crucial for replicating biological systems. The predictable velocity profile ensures adequate residence time for gas exchange in the lungs and nutrient transfer in other tissues.

Alveoli in the lungs demonstrate how small-scale fluid dynamics influence biological processes. Air flow through the tiny alveolar sacs remains laminar, allowing efficient gas exchange between air and blood. The smooth flow pattern prevents excessive turbulence that could damage delicate alveolar walls while ensuring adequate mixing for oxygen and carbon dioxide transfer. This biological system shows how evolution has optimized small-channel flow for maximum efficiency.

Practical Applications and Design Considerations

Microfluidic devices rely heavily on laminar flow characteristics for their operation. These devices manipulate tiny amounts of fluid for applications ranging from medical diagnostics to chemical synthesis. The predictable nature of laminar flow allows precise control over fluid mixing, reaction times, and particle separation.

Engineers designing heat exchangers for small-scale applications must carefully balance the trade-offs between laminar and turbulent flow. While turbulent flow provides better heat transfer, the associated pressure losses may require impractically large pumps. Many successful designs use enhanced surfaces or specially shaped channels to promote mixing while maintaining manageable pressure drops.

Manufacturing processes involving small channels, such as injection molding or 3D printing, depend on understanding flow behavior to ensure consistent results. The flow pattern affects how quickly materials fill complex geometries and influences the final product quality. Laminar flow provides more predictable filling but may create problems in areas requiring thorough mixing.

Conclusion

Researchers are exploring ways to improve mixing and heat transfer in laminar flow without the energy costs of turbulence. Passive methods use specialized channel designs to enhance performance, while active methods, like magnetic fields or acoustic waves, can switch between flow modes as needed.